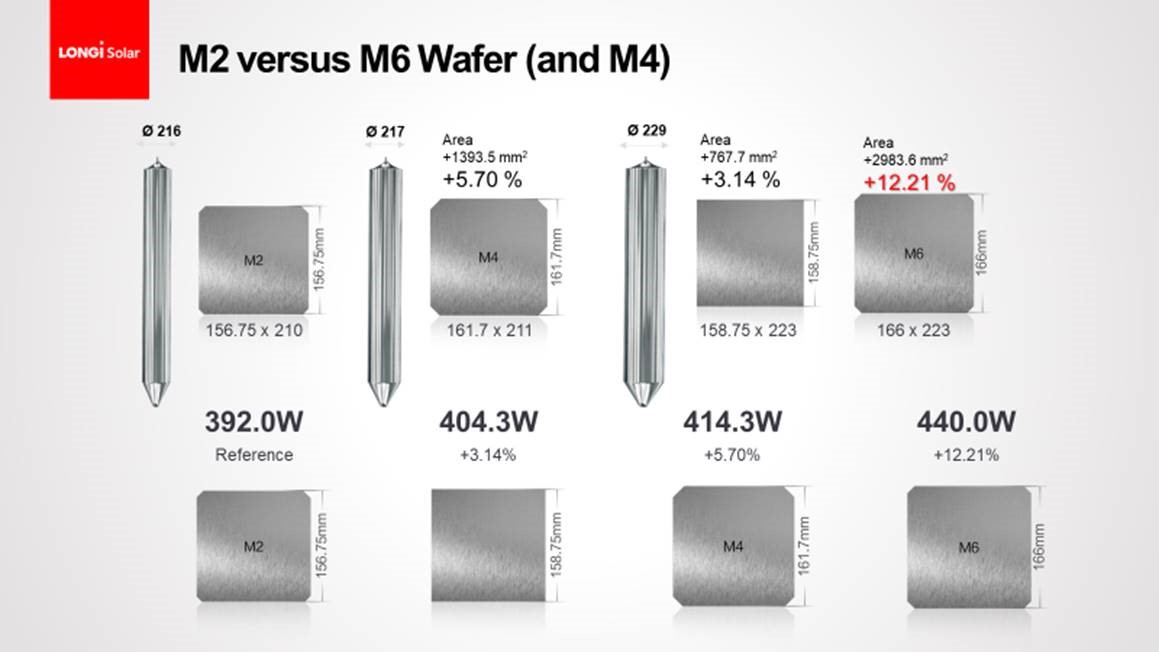

Jinkosolar began producing modules with 158 75 mm side length in 2018 lg went even further with 161 75 mm in as early as 2017 whereas canadian solar pushed their multicrystalline technology with 166 75 mm side length cells.

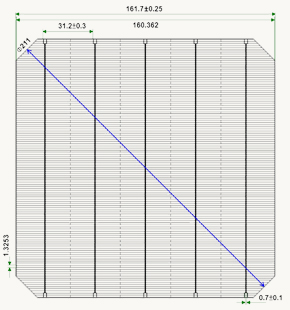

M4 solar wafer size.

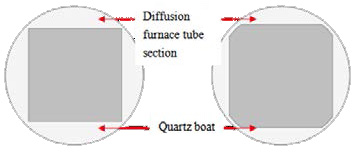

The process of manufacturing solar cells from single crystal p type silicon wafers is detailed below.

M4 wafers make better use of the ingot than m2 wafers help increase module power by 20 to 25 watts and thus support material and labor cost reduction during installation maximum output.

The demand for wafers has exponentially increased over the past two decades due to the increase in the production and sale of pv systems smartphones and more.

However improvements in cell efficiency appear to have hit a bottleneck making wafer size a hot topic among manufacturers once again.

At that time our taiwanese cell manufacturer went straight from m2 to the m4 with a size of 161 7 mm in order to only make necessary investment purchases once together with the multi busbar variant.

This time longi set the standard wafer size at 166mm and publicized the price of m6 mono wafers rmb 3 47 per piece us 0 49 showing its intention to the world for a powerful push of m6.

This was the driver for all cell producers to switch to the then larger wafer size after 2010 156mm x 156mm wafers increasingly became the popular choice lower cost per watt for p type mono.

Why wafer size matter.

This is the generalized method used based on a number of sources.

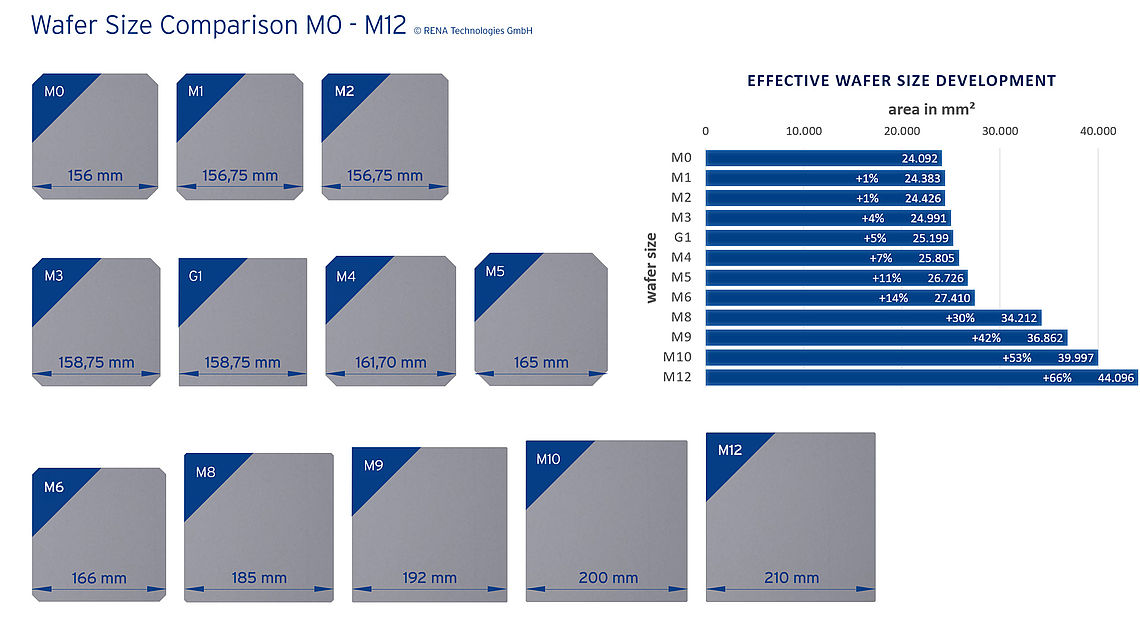

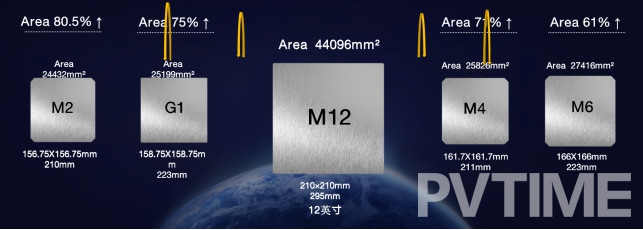

M1 m 2 m3 m4 m5 m6 m12 solar wafer and solar cell sizes m1 m2 m3 m4 m5 m6 and m12 are standard different wafer sizes used in the solar cell production process.

Solar wafer m12 g12 m10 m9 m6 g1 m4 m2 feb 23 2020 the larger the size the higher the power and the lower the cost leading the silicon industry to continue to introduce large size wafers from m2 m4 g1 m6 to m12 g12.

But now it appears a new milestone moment has arrived.

Since 2017 156 75 mm m2 wafers have been the standard.

Although m2 wafers are easy to integrate even larger wafer sizes are beginning to be used to obtain 400 w plus modules.