Thin electrical steels are available in one grade equivalent to m19 and are made by re rolling standard silicon steel.

M19 lamination steel.

Ak steel di max m 19 nonoriented electrical steel categories.

Aisi type equivalent of m15 m19 and m27 are astm equivalent of 36f145 36f155 and 36f175 respectively.

They all are non oriented electrical steel fully processed m15 are available in two.

More detailed information about these two types of steels can be found in the metals handbook.

The american iron and steel institute type numbers and ak steel designations for electrical steel grades con sist of the letter m followed by a number.

Electrical steel is usually manufactured in cold rolled strips less than 2 mm thick.

The number is representative of the core loss of that grade.

This inorganic surface treatment equivalent to astm type c 4 coating is produced by special chemical and thermal processing of the steel surface.

What is a lamination.

At the time the aisi system was adopted the type number assigned to each grade.

Small hysteresis area resulting in low power loss per cycle low core loss and high permeability.

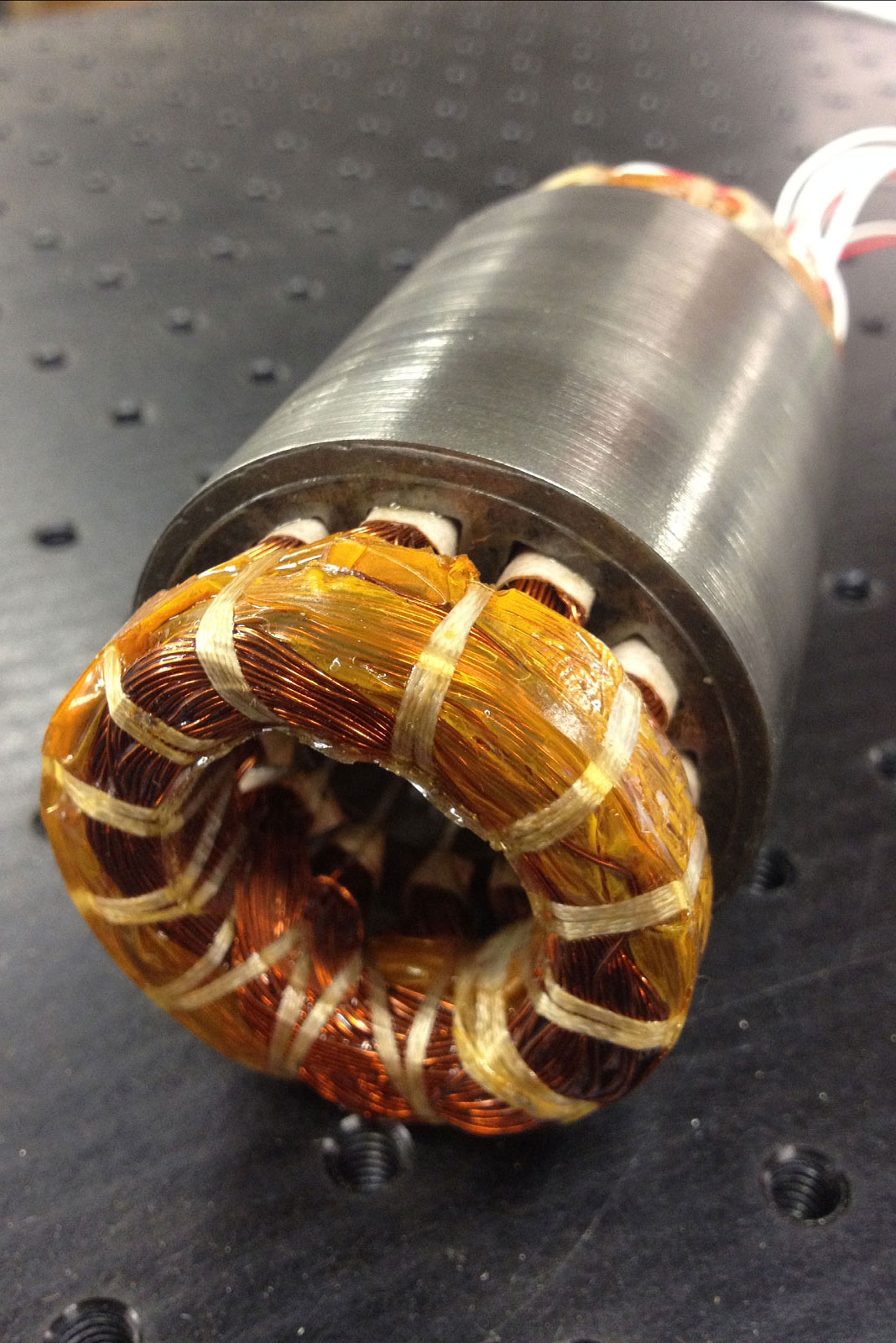

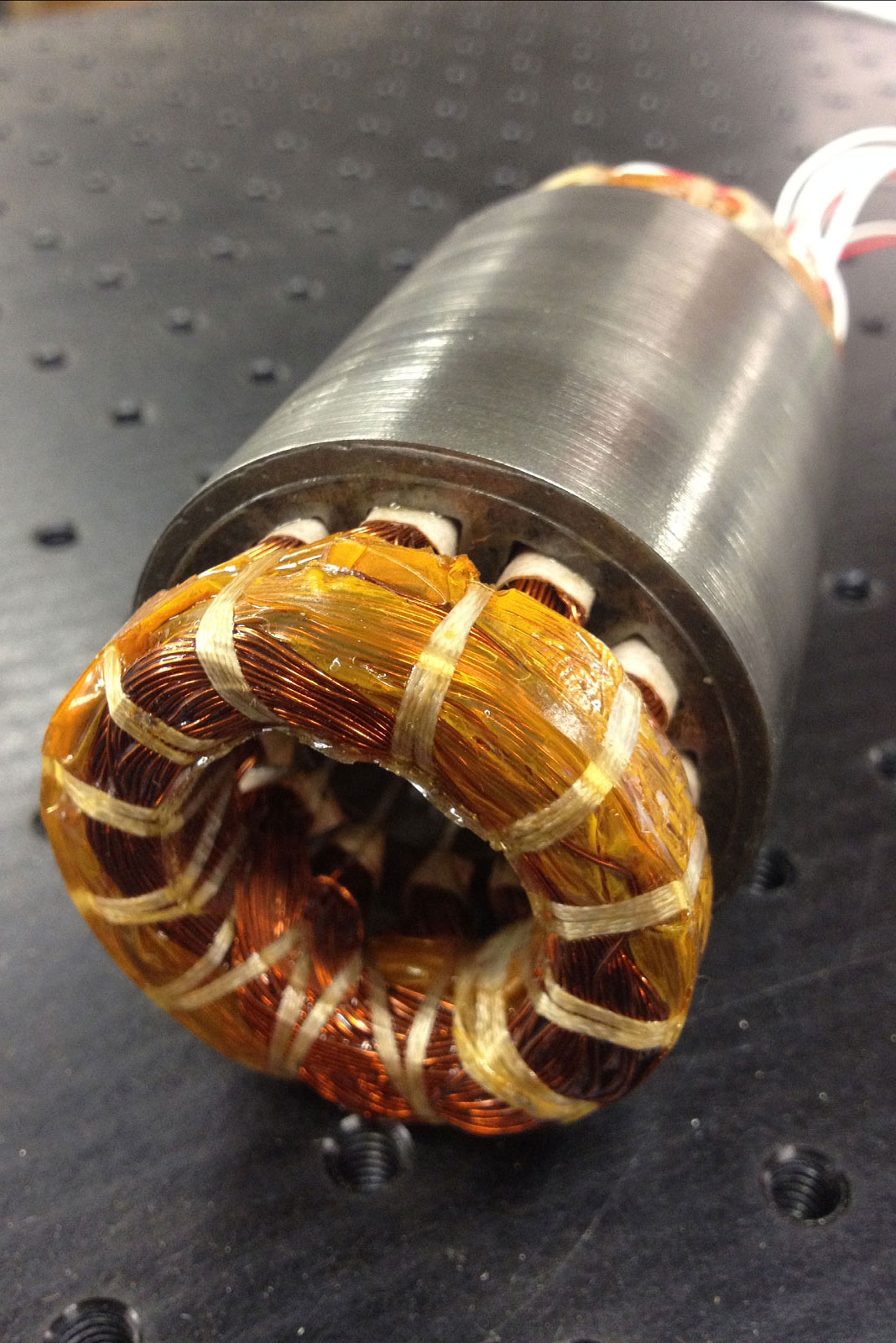

Electrical steel lamination steel silicon electrical steel silicon steel relay steel transformer steel is an iron alloy tailored to produce specific magnetic properties.

Electrical steel also called lamination steel silicon electrical steel silicon steel relay steel or transformer steel is specialty steel tailored to produce certain magnetic properties such as a small hysteresis area small.

C 4 insulation is best for punched laminations where only a moderate degree of surface insulation is required but good die life and minimum effect on lamination factor are very important.

Due to substantially higher material cost thin electrical steel is used primarily for high performance and high frequency applications.

There are two types of electrical steels used for rotor laminations semi processed and fully processed.

Nonoriented electrical steels are silicon steels in which magnetic properties are practically the same in any direction of magnetism in the plane of the material.

The m stands for magnetic material.

Thickness mm core loss 1 5t 50hz.